(P) Traceability - NC Vision creates innovative solutions: Case Study COINDU

Spectacular recalls are increasingly making headlines (see article here). In this context, one usually comes across the term traceability. But what exactly does the traceability of products mean and why is it so important for quality management, especially for manufacturing companies? Why can the consistent traceability of manufactured products protect companies from uncoordinated recalls, thereby secure the confidence of customers?

The aim of a traceability system is to link the physical flow of goods with the flow of information and to ensure complete documentation of all stages on the supply chain and production. All quality-relevant data of all production steps are traceably determined and stored by the traceability system. This allows companies to easily and quickly identify when, where and by whom their products were produced, how and which suppliers were involved, and to which customers the products were delivered. In the event of production failures, the cause of the error can be determined quickly and an efficient recall of all affected batches can be initiated at the customer. Powerful traceability systems automatically link external supplier and customer data as well as internal data sources, e.g. IOT or robot, and logistics processes (goods receipt, inventory, goods issue, production control). This ensures product quality and traceability in the traceability system.

For this purpose, the systems prevent errors in production, increase product and process quality as well as efficiency and reduce costs.

COINDU

Outstanding product quality, flexible production processes and the resulting high level of customer satisfaction are COINDU's recipe for success. The global manufacturer of leather seat covers for cars (6,000 employees, 4 locations in Portugal, Romania, Mexico and Germany, 348 million sales in 2018) supplies the "Who is Who" of the automotive industry and has been supplying this with increasing sales for years. Traceability plays a major role at COINDU in order to meet the high quality requirements of COINDU and COINDU customers. At the site in Curtici near Arad, COINDU-Quality Management identified further potential for quality improvement. Due to the complexity, the implementation was an IT technical challenge and could not be accomplished with the existing IT Traceability systems. In the search for a suitable external IT partner, NC-Vision GmbH in Arad/Romania was chosen in the immediate vicinity of COINDU.

Dan Meruta - Quality Manager: "We decided on NC-Vision because the CATS Traceability Software solution flexibly maps our specific COINDU requirements within the product standard. To this end, we have the best experience with the people involved from previous IT projects."

Together, the two companies set to work. An optimal solution for the COINDU task had to be found. In particular, the distinctiveness and the incomprehensibility of left and right car seat covers were a challenge. To solve this, existing processes had to be supplemented with complex validation systems. In the validation system, machine and IOT Data, as well as manual input data from humans, are processed together to ensure proper assembly. For this purpose, the generated data must be transferred to the COINDU ITsystems.

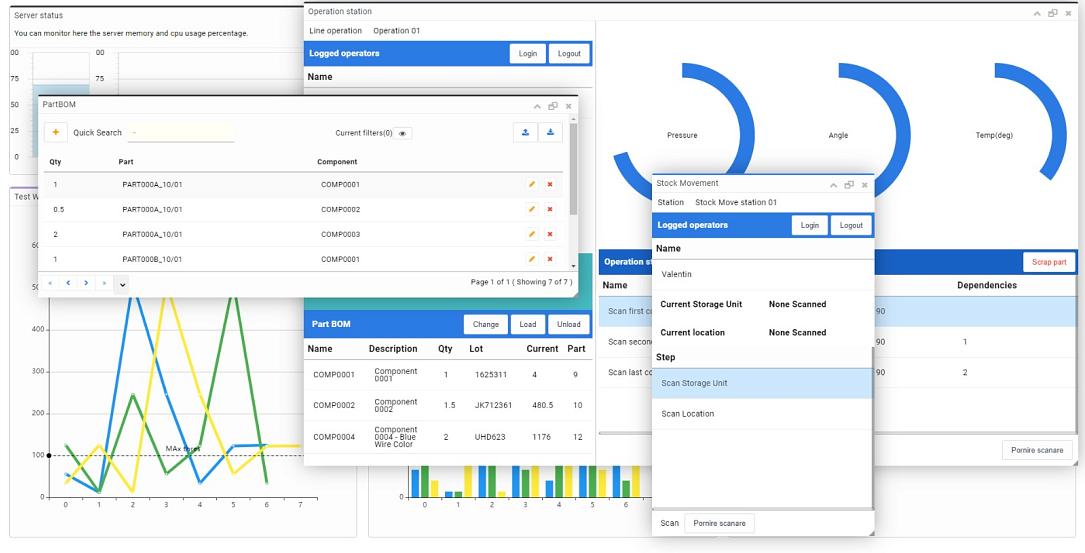

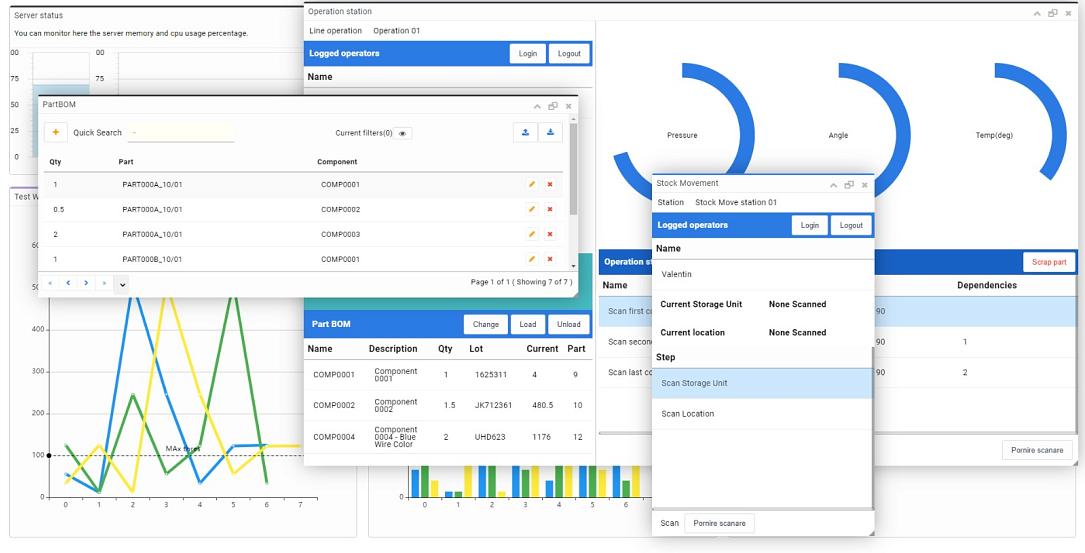

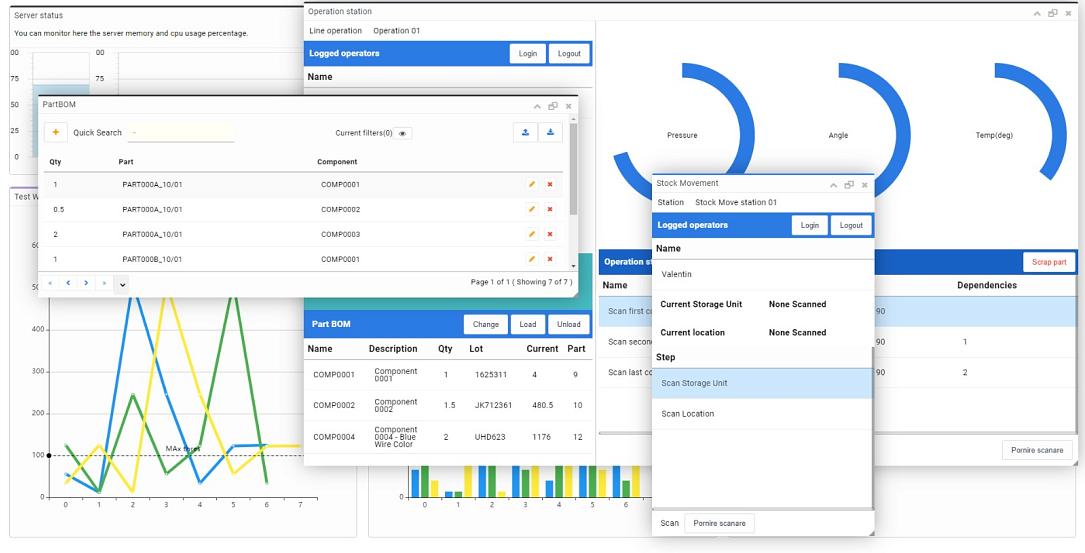

The implementation of the solution was very easy with NC-Vision. NC-Vision analyzed the task in a requirements workshop and created a solution concept on this basis. COINDU has reviewed the solution concept and NC-Vision has provided a customized CATS Traceability Solution (sample of the CATS User Interface in the opening picture) within a few days. This COINDU solution was tested together in a single day and put into productive operation. Since then, the solution has run without any problems. All in all, in a record time of just over two weeks. CATS is currently being rolled out to other production lines and locations.

Dan Meruta - Quality Manager, is enthusiastic: "We are very satisfied. In a short time, NC-Vision has perfectly put the CATS Traceability software solution into operation and thus solved our problem. This improves our product quality and customer satisfaction."

In the next material, you will read more about NC-Vision, what motivates the founders, what vision they have and how they want to conquer the Romanian market.

NC-Vision is a German-Romanian software company, founded in 2019 specializing in traceability solutions for manufacturing companies. With decades of experience in traceability projects and software technology, NC-Vision develops and distributes the innovative traceability software solution CATS. At the locations in Arad and Biberach an der Riss (Germany), the two founders Klaus Heller and Florentin Szomoru will start their way in 2020.

For more information check our website here.

Contact: sales@nc-vision.com

(p) - This article is an advertorial.